Liberty Energy has updated and expanded our Bettering Human Lives report. Issued in January 2024, the third edition of this report contains an in-depth look…

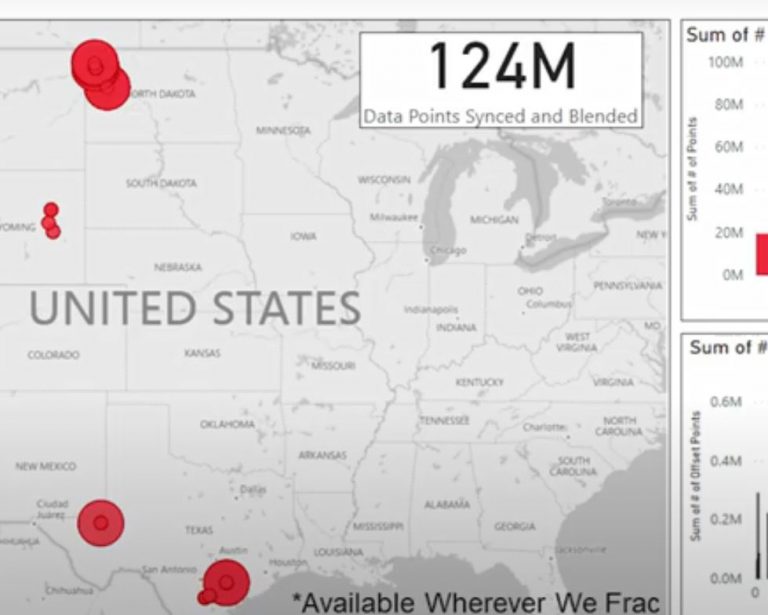

Liberty’s Sentinel platform stands out as an advanced system that can harness real-time data from every frac location to provide insight into current operations and…

At Liberty, we bring great people together in a culture of excellence to deliver superior service quality to our partners (customers). We are leaders in…

While the benefits of the shale revolution are manifest, nothing comes for free. Nothing is without impact. Liberty and our whole industry work tirelessly to…

This week, Liberty’s Pressure Control Equipment Lead, Janet Fuchs, is breaking down each element of pressure control equipment used on wireline locations, as well as…

Join Liberty Demand Management Engineer, Ryan Wachtstetter, as he discusses the different cable types in today’s industry as well as why greaseless wireline is the…

Liberty Account Representative, Grace Bol, discusses perforating guns: how they came about, how they are used, and the basic mechanics of this wireline component. Download…

Wireline Manager, Felix Dorante, gives a brief introduction into Liberty’s new product line and a basic overview on “What is Wireline?”

Friction along the wellbore, through the perforations and the near-wellbore area of the fracture can hide from us what is truly happening with frac pressures…

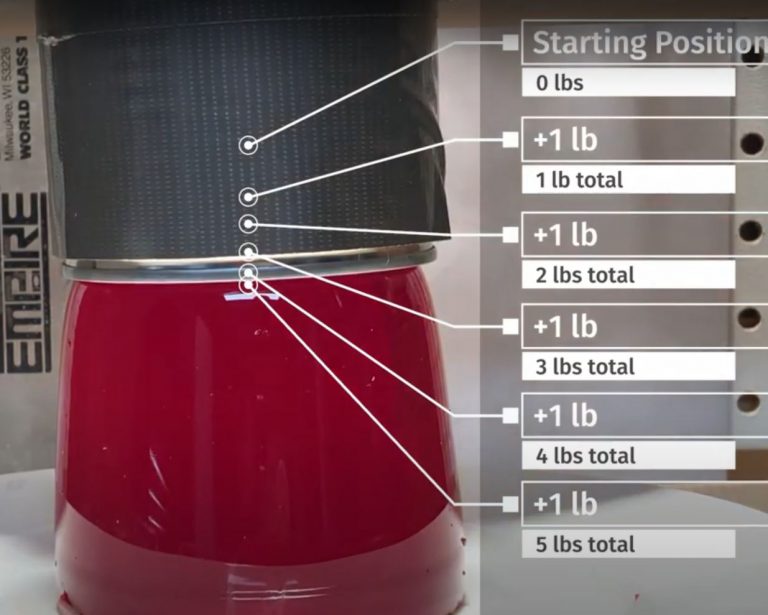

In this home educational video, VP of Engineering, Leen Weijers, inflates the tire of his wheel barrow to introduce concepts of net pressure and closure…

Hydraulic Fracturing has been around since 1947 – and a lot has changed since then. Dr. Ouigee (Leen Weijers) breaks down the evolution of shale…

Natural gas occurs naturally in many more places than you think. Doc Ouigee explores wetlands and ponds near his CO home to find natural gas…

Liberty’s Doc Ouigee demonstrates in his Home Frac Lab how we can measure Poisson’s Ratio and why it is important for frac design optimization. Download…

Fracking is not just about breaking rocks. It is also about pushing rock out of the way! How easy that is depends, amongst others, on…

Diversion strategies during the frac can help maximize the number of perforation clusters that effectively take frac fluid and proppant, thus ensuring that these clusters…

How much effort does it take to fracture rocks? Learn about fracture growth through laminations in this Liberty Educational Video with Dr. Leen Weijers. Download…

An update from Dr. Leen Weijers, Liberty’s VP of Engineering on continuing to minimize dollars per barrel of oil. This video expands on a presentation…

Liberty’s Lab Manager, Joel Siegel, talks about the tools we use in our labs to to design fluid systems and ensure they behave as designed.…

Liberty’s Engineering Manager, Ben Poppel provides a quick rundown of powder vs. slurry fluid systems and what solution is right for the job.

Looking for a quick overview on tight perf cluster spacing? Curious about how conductivity optimization should be performed? This video, featuring our Director of Technology,…

Discover the concepts of porosity and permeability and how they relate to frac’ing in this educational video from Liberty’s VP of Engineering, Dr. Leen Weijers.…

WellWatch brings off-pad well pressure and other data directly to the Liberty data van, where operators can use this information for more efficient frac-protects and…

Engineering Manager Ben Poppel discusses Liberty’s switch in product to improve chemical health and safety on location. Download PDF

Liberty invention for urban fracking reduces noise level more than 3X as compared to a conventional fleet.

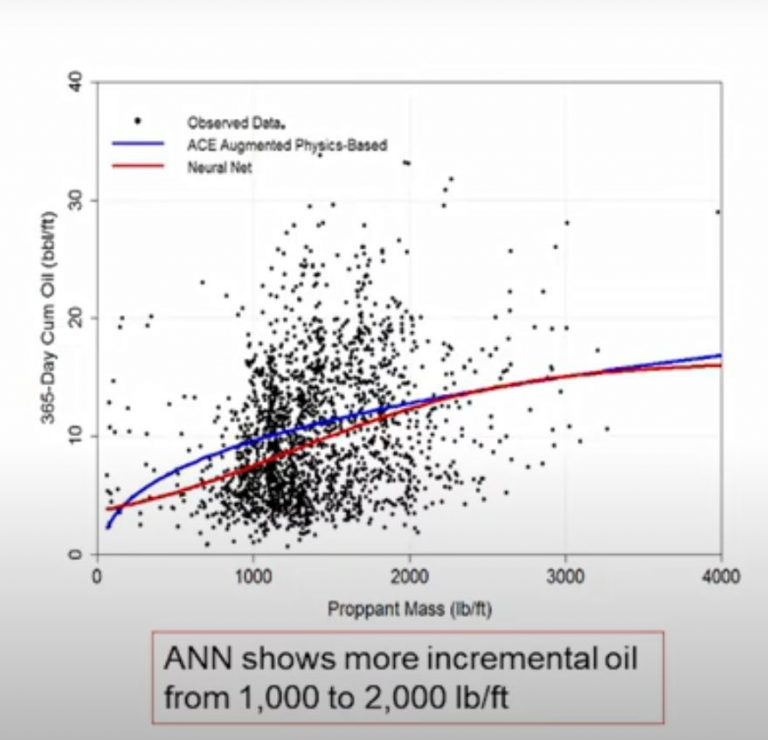

Director of Technology, Mike Mayerhofer, talks about using neural networks to optimize completions in the Midland Basin. Download PDF

Liberty’s President, Ron Gusek, explains how wear and tear on pumping equipment and iron on a frac location may be dramatically reduced through the use…

Liberty’s Lab Director, Joel Siegel, discusses the benefits of using Liberty’s Flowloops to test the effectiveness and cost saving potential of different chemicals used in…

Joel Siegel, Liberty’s Lab Director, explains the uses of our ICP-OES apparatus’. These machines test for elements in produced water that can cause formation damage…

Liberty’s wide range of engineering services help our customers “spiral up” from data to value. Our VP of Engineering, Leen Weijers, walks you through the…

In this video, Liberty’s Engineering Manager, Ben Poppel, addresses the preconceived notions that both ultra-low polymer cross-linked gels and high viscosity polyacrylamide fluid systems are…

Senior Technical Sales Engineer, Kyle George, gives a brief overview of the methodology Liberty uses to evaluate friction reducers and how we select them from…

Determining the proper well spacing in shale development is a multi-million dollar question. Dr Mike Mayerhofer shows how Liberty can help with calibrated frac and…

Liberty CEO, Chris Wright, shares his top 10 reasons to love oil and gas. Download PDF

Learn more about the Log Library Liberty uses, and why this matters to you. Download PDF

Need a refresher on net fracturing pressure and slurry efficiency? This video is for you! VP of Engineering, Leen Weijers, walks you through concepts that…

Plug&perf and a limited entry perforation strategy can create more control over the fracture initiation process and a more favorable near-wellbore fracture geometry. Download PDF

Since 2013, Liberty has been collecting and testing samples of proppant from every single pad we have fracked. This is done to ensure our customers…

Engineering Manager Ben Poppel explains that acid-replacement SpearPoint has the same bottom hole reactivity to open perforations without the HSE-impact for our employees to handle…

Why would you spend money on a tensiometer? Liberty Lab Manager Joel Siegel explains why it’s worth it. Download PDF

A new whitepaper from Roy Aune, Chris Wright, and Madison Hollaway that analyzes a parallel shift towards natural gas’ growing role in powering hydraulic fracturing…

Presence of bacteria can have a long-term impact on reservoir performance. Liberty Sr. Staff Engineer Kyle George explains that Liberty can monitor for bacteria during…

Last-mile logistics solution that dramatically reduces dust and noise on a frac location, while also reducing truck traffic for more efficient delivery.

Lindsey Moore, Liberty Staff Engineer, reviews Liberty’s unsurpassed library of regained conductivity test (as conducted by PropTester), helping us to recommend and utilize fluid systems…

Ever wondered about the Modified Mayerhofer analysis in a DFIT evaluation. Oracle Doctor Mayerhofer himself explains Liberty’s DFIT analysis strategy. Download PDF

A DFIT provides vital anchor points for Liberty’s frac design recommendations. Liberty’s Director of Technology Mike Mayerhofer explains why. Download PDF

Liberty Hazard Communications Specialist Anita Stelly explains how we use a chemical additive rating program based on Global Health Systems to help make greener selections…

Liberty partners with oil & gas operators to incorporate their in-house completion data in LibertyMVA and Fraconomics to create value. Download PDF

A Liberty methodology to evaluate potential swelling clays and the appropriateness of a KCl-substitute. Download PDF

Liberty’s modeling tools can help to maximize complexity and fracture surface area through the evaluation of various fracture treatment sequences in multi-well completions. Download PDF

Dr. Mike Mayerhofer, Liberty’s Director of Technology, provides his data-driven perspective on the impact of Brown Sand vs White Sand on oil production in the…

Pre-job screen-out assessment and evaluation of stage injectivity during fracture treatments as driven by proximity to faults and MWD/lateral log properties. Download PDF

Liberty’s surface and interfacial tension measurements on drill cutting can help select the most appropriate and economic surfactant for the job. Download PDF

A discussion of potential challenges in the “perfs open” calculation of the rate stepdown test. Download PDF

Liberty determines statistical production drivers and combines this with fracture treatment cost sensitivities to minimize our client’s production cost per barrel oil ($/BO). Download PDF

An ultra-sonic measurement of fluid levels in tanks to more safely and accurately determine consumed chemical additive volumes during a frac job. Download PDF

Elasticity measurements at low shear rates in high-viscosity friction reducers (HVFR) can help reduce fluid cost and ensure efficient transport of proppant. Download PDF

Liberty provides a proprietary viewer of completion and production data for liquid-rich basins to help operators spot trends in production drivers. Download PDF

Statistical analysis that provides an assessment of independent completion and geological parameters that drive production. Download PDF

An ultra-low concentration frac fluid system that can help reduce job cost and reservoir damage. Download PDF

Did you know that frac fluid can be made using simple products available at your local grocery store? Our lab manager, Joel, whips up a…

Liberty’s Rock Doc and VP of Engineering, Dr. Leen Weijers, has three experiments to explain how fractures start to grow.

A simple frac fluid with high viscosity can be made using a four commonly-used grocery-sourced materials.

Liberty’s unique tech team background has always forcused on learning from direct fracture diagnostics. Fracture model calibration is the first step in understanding the economic…

The signature Liberty 2Cs Design creates fracs with Complexity with sufficient Conductivity to result in some of the best Bakken producers. Liberty’s method of breaking…

Completion engineers and geologists always argue about where credit is due for better producing wells: better rock or better fracs? We have developed a comparison…

As the shale development progresses, the industry seeks to apply more sustainable practices which includes the recycling of produced water. It is on a slippery…

Anyone can conduct multi-variate analysis (MVA) and come up with correlations between possible cause and effect. But the results can often be complete madness. It…

Many things change during an industry downturn, but one goal always remains: a need to reduce cost per produced barrel of oil equivalent, or in…

For several years prior to 2014 the DJ Basin was a service company paradise, where the completion method was directed by service companies at the…

Black Hills Exploration and Production helped substantiate the USGS estimate by completing a number of 8,000- to 10,000-foot horizontal wells in the Niobrara Formation in…